PSA

If you are looking for oxygen generator at higher generating pressure then PSA Oxygen Generator is for you.

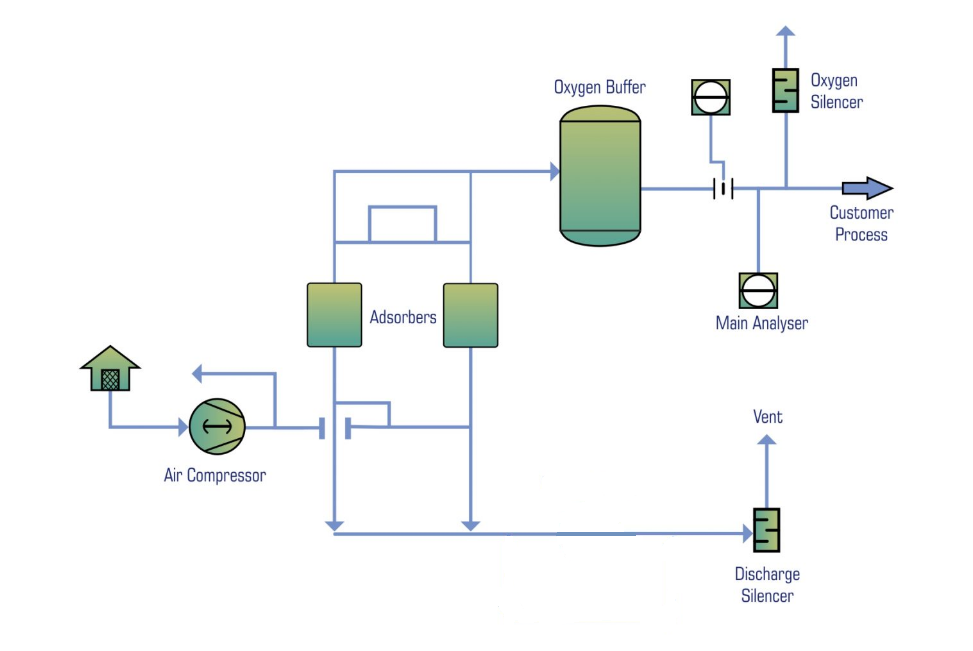

PSA oxygen generator process utilized by BRISE CHEMICALS plants is a method of separating air into its two principal components—Nitrogen and Oxygen— using adsorption technology at high pressure. Ambient air from the atmosphere is compressed in an Air Compressor up to 116 PSIG and is routed through a pre-filter to remove particulate material and then sent to Refrigeration dryer system which maintains the refrigeration process at temperature less than dew point (< 3 deg C) to remove moisture present in ambient air. Dry air from refrigeration dryer system is sent to an Air Receiver. Dry air from air receiver is routed through a series of filters viz. fine filter and activated carbon filter to safeguard the PSA system from any fine particles and hydrocarbon/oil traces. Clean dry air from the activated carbon filter is routed to the PSA oxygen generator system for adsorption.

There are four main phases of the pressure swing adsorption process:

- 1. Adsorption: The adsorber starts off pressurized with pure gas. The impure gas is fed into the column which contains the adsorber. Adsorption takes place and the pure gas is released from the top of the column. This takes place until the adsorber saturation.

- 2. Depressurization: The adsorber is depressurized over in several small steps to recover additional pure gas still in the adsorber. Once all pure gas has been recovered, the desorbed impurities are vented back into the atmosphere.

- 3. Regeneration: The adsorbent is purged with high-purity gas at constant off-gas pressure to further regenerate the adsorbent bed.

- 4. Repressurization: The adsorber is repressurized with pure gas and is now ready to receive more feed gas to start the process over.

Features and Benefits

- High product pressure

– Adsorption performed at 60-70 PSIG

- Low Capital Cost

– Highly skidded and modular design

- High Reliability

– Fully automatic controls

– Designed for unmanned operation

Process Flow

Product Offering

| Parameter | Specification |

|---|---|

| O₂ production capacity | 50–500 Nm³/h (2–17 tpd) |

| O₂ purity | 90–95 vol.% |

| Vacuum pump | No |

| Containerized units | No |

| Operating pressure | ATM to 116PSIG |