Nitrogen

Scientists and researchers use liquid nitrogen (LN2) to store and preserve biological materials. Liquid nitrogen is the liquid state of the element nitrogen and is classified as a cryogenic liquid (temperatures below -150°C – -273°C). Overall, liquid Nitrogen is an essential tool for scientific research. Other than that it’s used in various other industries. Hence it’s important that it is stored and transported correctly in its liquid form for accessibility and cost-effectiveness and safety.

Due to liquid nitrogen being a cryogenic liquid, the temperature difference between the product and the environment is significant. To keep this surrounding heat away from the product, cryogenic Nitrogen storage tank manufacturers makes special liquid nitrogen storage tank that can handle its requirements.

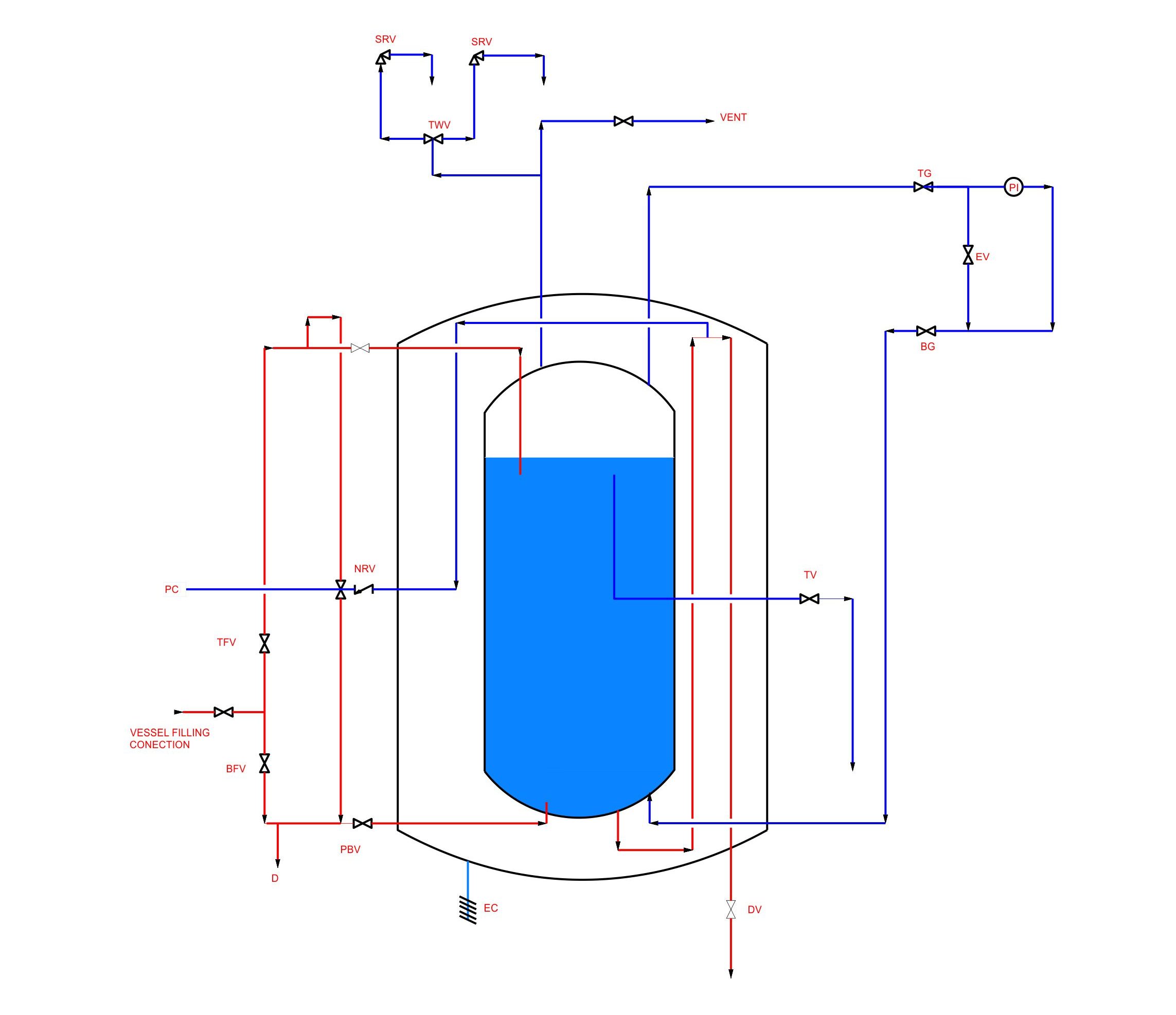

Process Flow Diagram

What Will Happen if Liquid Nitrogen Is Not Stored Properly

If not properly stored and handled liquid nitrogen can be quite hazardous. The followings are some of the serious issues that can take place if not stored properly.

One Can Get Cold Burns

Because of its extremely low temperature, the cold vapor and gas produced when LN2 boils can cause cold burns or frostbite when it comes into contact with unprotected skin. Exposure can also cause breathing difficulties and Asphyxiation.

Pressure Buildup Can Cause an Explosion

Because of the large expansion ratio (liquid to gas), when liquid nitrogen evaporates in a closed system, pressure can build up, posing a high risk of explosion. If there is no relief vent, ice plugs can form on the neck of narrow storage vessels because LN2 readily condenses water to form ice. As a result, pressure will build up in the storage tank

About Brise Cryogenic Liquid Storage Tank- for LIN, LOX & LAR

The main aim of a Cryogenic liquid Nitrogen storage tank is to keep the surrounding heat at bay as explained before. It consists of the main tank, a vaporizer, and a pressure control manifold. The Tank can be either cylindrical or spherical in shape depending on the manufacturer’s preferred design. For ease of transportation, they are mounted in fixed locations as stationary vessels or on a car or truck chassis. The tanks range in size from 500 to 420,000 gallons, and the annular space is powder- and vacuum-insulated. Various circuits are installed in tanks to control product fill, pressure buildup, pressure relief, product withdrawal, and tank vacuum.

Advantages of Cryogenic Liquid Storage Tank

- Easy Accessibility for Medical PurposesThe tank, along with vaporizers, valves, piping, and pressure control and pressure relief system, forms a vacuum-insulated evaporator (VIE), which can supply a medical facility’s central oxygen piping system and is frequently leased from the medical gas supplier. Because oxygen enters the piping system after passive evaporation in the vaporizer, no power source is required. VIEs can also be configured to fill cylinders without the use of electricity.

- Cheaper and Less BulkyBecause one liter of liquid oxygen produces 861 liters of gaseous oxygen, transporting and storing it as a liquid takes less space and is less expensive than moving and storing it as a gas under high pressure. Although liquid oxygen is cost-effective for large-scale facilities, the bulk liquid used to fill the tanks is produced at a cryogenic air separation unit (ASU) and requires a specialized bulk road tanker to transport from the ASU to the VIE. While investing in cryogenic storage tanks go with well-reputed cryogenic storage tank manufacturers like Brise Chemical as are poorly made tanks that can be a serious health and financial hazard.

- Ease of Transportation and Loading ProcessThey are intended for easy transport and storage without any spillage. These innovative sturdy tanks are built to last and are made for easy handling. They highly improve stability and safety.

- No ContaminationContamination with any external agents is eliminated completely since liquid nitrogen gets stored in cryogenic tanks and is always isolated in a hermetically sealed container.

- Efficiency In OperationThese tanks are easy to handle, can be transported long-distance, and is quite durable and sturdy. They are cost-efficient, and longer storage time helps with increasing efficiency in operation.

- Temperature PreservationWith proper sealing they curtail evaporation and retain the inside temperature, thus protecting the element from any outside interference.

- Safety and RelianceThey are durable enough for prolonged usage and act as a safeguard against certain physical hazards like asphyxiation. The risks are kept to a minimum because these cryogenic liquids are kept isolated in hermetically sealed, stable tanks with no contact with the outside world. Cylinder transfer within the facilities is avoided, avoiding unnecessary risks. While investing in cryogenic storage tanks go with well-reputed cryogenic storage tank manufacturers like Brise Chemical, as poorly made tanks can be serious health and financial hazard.

Cryogenic Liquid Storage Tank Applications Across Industries

- Food and Beverage Industry

- chemicals and pharmaceuticals Industry

- Metal manufacturing and Construction Industry

- Healthcare Industry

- Scientific Research

- Electronics Industry

- Rubber and Plastic Industries

- Others

Product Offering

| TFV – Top Filling Valve |

| BFV – Bottom Filling Valve |

| TG – Top Gauge |

| D – Discharge |

| PBV – Pressure Building Valve |

| PBC – Pressure Building Coil |

| PC – Pressure Control |

| NRV – Non Returning Valve |

| DV – Discharge Valve |

| EC – Evacuation Connection |

| TV – Try Cock Valve |

| BD – Brust Disk |

| LI – Level Indicator |

| PI – Pressure Indicator |

| EV – Equalization Valve |

| SRV – Safety Relief Valve |

| TWV – Three Way Safety Diversion Valve |

| Size | 3KL | 6KL | 10KL | 15KL | 20KL | 25KL | 30KL | 35KL | 40KL | |

|---|---|---|---|---|---|---|---|---|---|---|

| Max Allowable Pressure | Bar | 18.36 | ||||||||

| Gross Capacity | Approx. Lit | 3000 | 6000 | 10000 | 15000 | 20000 | 25000 | 30000 | 35000 | 40000 |

| Approx. Lit (@18 bar) | 2850 | 5700 | 9500 | 14250 | 19000 | 23750 | 28500 | 33250 | 38000 | |

| Pressure stage 18 bar filling ration 95%,1 bar | Approx. Lit (@36 bar) kg LIN |

2850 2303 |

5700 4604 |

9500 7676 |

14250 11514 |

19000 15352 |

23750 19190 |

28500 23028 |

33250 26866 |

38000 30704 |

| kg LOX | 3240 | 6481 | 10802 | 16202 | 21603 | 27004 | 232405 | 37805 | 43206 | |

| 36 bar filling ratio 90%,1bar | kg LAR kg LIN |

3976 2182 |

7952 4363 |

13253 7272 |

19879 10908 |

26505 14544 |

33131 18180 |

39758 21816 |

46384 25452 |

53010 29088 |

| kg LOX | 3070 | 6140 | 10233 | 15350 | 20466 | 25583 | 30699 | 35816 | 40932 | |

| Boil off rate 1 bar,15 °C A>T | kg LAR %/d LIN |

3767 0.69 |

7533 0.62 |

12555 0.44 |

18833 0.32 |

25110 0.32 |

3188 0.23 |

37665 0.23 |

43943 0.23 |

50220 0.23 |

| %/d LOX | 0.44 | 0.41 | 0.29 | 0.21 | 0.21 | 0.15 | 0.15 | 0.15 | 0.15 | |

| %/d LAR | 0.463 | 0.44 | 0.32 | 0.23 | 0.23 | 0.16 | 0.16 | 0.16 | 0.16 | |

| Discharge capacity with standard pressure building coil at 0.7 × MAWP and 8 hours operating time pressure stage | ||||||||||

| 18 bar | m³/h(1 bar,15 °C)LIN | 150 | 300 | 600 | ||||||

| 18 bar | m³/h(1 bar,15 °C)LOX | 190 | 380 | 750 | ||||||

| 18 bar | m³/h(1 bar,15 °C)LAR m³/h(1 bar,15 °C)LIN |

190 140 |

380 140 |

750 280 |

||||||

| 18 bar | m³/h(1 bar,15 °C)LOX | 180 | 180 | 360 | ||||||

| 18 bar | m³/h(1 bar,15 °C)LAR | 180 | 180 | 360 | ||||||

| Capacity of one safety valve at 1.1 MAWP / cold condition | ||||||||||

| 18 bar | Kg/h LIN Kg/h LOX Kg/h LAR |

1090 1010 1240 |

||||||||

| 18 bar | Kg/h LIN Kg/h LOX Kg/h LAR |

5610 2260 2850 |

||||||||

| Insulation | Insulating powder(Perlite(,vacuum <5*102mbar(tank in operation) | |||||||||

| Main Material | Inner vessel | Low temperature resistant Stainless Steel | ||||||||

| Outer vessel | Carbon Steel | |||||||||

| Diameter | mm | 1560 | 1610 | 1980 | 2410 | 2410 | 3060 | 3060 | 3060 | 3060 |

| Height | mm | 4190 | 7150 | 6560 | 5870 | 7630 | 5400 | 6370 | 7340 | 8305 |