Oxygen

When we think of oxygen, we think of living itself, since O₂ is what helps sustain life on this planet. It is the second-largest component of the atmosphere by volume, accounting for approximately 21 percent of all air. Without oxygen, we all will cease to exist. However, oxygen is used for more than just breathing and has numerous other applications in a wide range of industries. This is why cryogenic storage tank manufacturers create cryogenic oxygen storage tanks to store O2 in liquid form for a variety of industrial and medical purposes.

Cryogenic liquids are liquefied gases with normal boiling points lower than –150°C. And liquid oxygen is a cryogenic liquid with a boiling point of –183°C. Because the temperature difference between the product and the surrounding environment is significant-it is critical to. Keep liquid oxygen insulated from the surrounding heat. This is why special equipment like cryogenic oxygen storage tanks are needed for proper handling and storage.

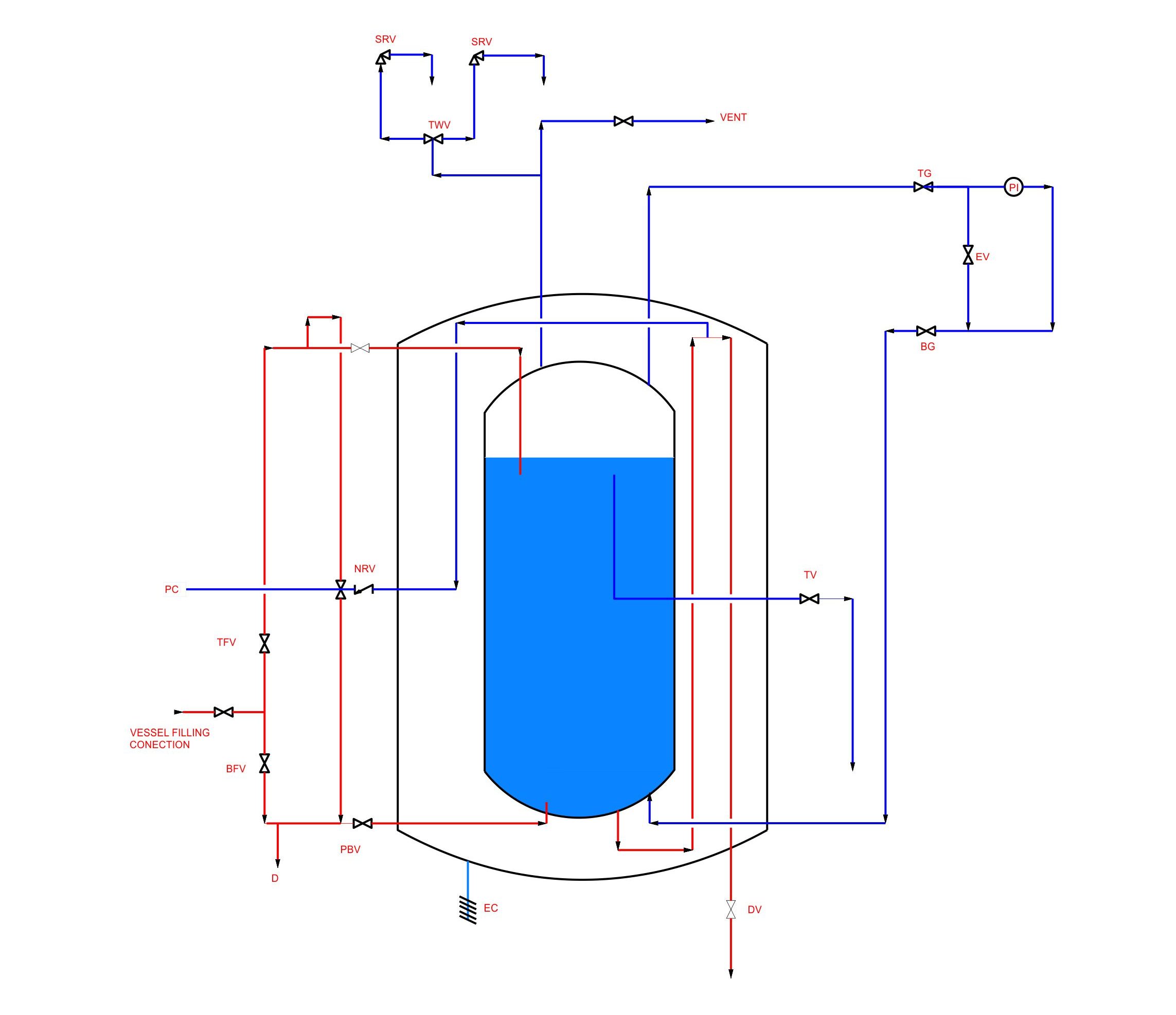

Proccess Flow Digram

What Will Happen if Liquid Oxygen Is Not Stored Properly?

Even though it is one of the main ingredients for creating life, it can also be life-threatening in its liquid form. Some of the major issues it can cause if not properly stored are listed below.

- Contact with liquid oxygen can result in severe skin and eye irritation, burns, and frostbite.

- Although oxygen is not flammable, it promotes combustion and significantly increases the intensity of a fire. Continuous exposure to pure oxygen can cause severe convulsions and even death

Cryogenic Oxygen Storage Tank Applications Across Industries

- Health and Medical Industries

- Metal Industry

- Chemical and Petroleum Industries

- Pulp and Paper Industries

- Wastewater Treatment Industries

Product Offering

| TFV – Top Filling Valve |

| BFV – Bottom Filling Valve |

| TG – Top Gauge |

| D – Discharge |

| PBV – Pressure Building Valve |

| PBC – Pressure Building Coil |

| PC – Pressure Control |

| NRV – Non Returning Valve |

| DV – Discharge Valve |

| EC – Evacuation Connection |

| TV – Try Cock Valve |

| BD – Brust Disk |

| LI – Level Indicator |

| PI – Pressure Indicator |

| EV – Equalization Valve |

| SRV – Safety Relief Valve |

| TWV – Three Way Safety Diversion Valve |

| Size | 3KL | 6KL | 10KL | 15KL | 20KL | 25KL | 30KL | 35KL | 40KL | |

|---|---|---|---|---|---|---|---|---|---|---|

| Max Allowable Pressure | Bar | 18.36 | ||||||||

| Gross Capacity | Approx. Lit | 3000 | 6000 | 10000 | 15000 | 20000 | 25000 | 30000 | 35000 | 40000 |

| Approx. Lit (@18 bar) | 2850 | 5700 | 9500 | 14250 | 19000 | 23750 | 28500 | 33250 | 38000 | |

| Pressure stage 18 bar filling ration 95%,1 bar | Approx. Lit (@36 bar) kg LIN |

2850 2303 |

5700 4604 |

9500 7676 |

14250 11514 |

19000 15352 |

23750 19190 |

28500 23028 |

33250 26866 |

38000 30704 |

| kg LOX | 3240 | 6481 | 10802 | 16202 | 21603 | 27004 | 232405 | 37805 | 43206 | |

| 36 bar filling ratio 90%,1bar | kg LAR kg LIN |

3976 2182 |

7952 4363 |

13253 7272 |

19879 10908 |

26505 14544 |

33131 18180 |

39758 21816 |

46384 25452 |

53010 29088 |

| kg LOX | 3070 | 6140 | 10233 | 15350 | 20466 | 25583 | 30699 | 35816 | 40932 | |

| Boil off rate 1 bar,15 °C A>T | kg LAR %/d LIN |

3767 0.69 |

7533 0.62 |

12555 0.44 |

18833 0.32 |

25110 0.32 |

3188 0.23 |

37665 0.23 |

43943 0.23 |

50220 0.23 |

| %/d LOX | 0.44 | 0.41 | 0.29 | 0.21 | 0.21 | 0.15 | 0.15 | 0.15 | 0.15 | |

| %/d LAR | 0.463 | 0.44 | 0.32 | 0.23 | 0.23 | 0.16 | 0.16 | 0.16 | 0.16 | |

| Discharge capacity with standard pressure building coil at 0.7 × MAWP and 8 hours operating time pressure stage | ||||||||||

| 18 bar | m³/h(1 bar,15 °C)LIN | 150 | 300 | 600 | ||||||

| 18 bar | m³/h(1 bar,15 °C)LOX | 190 | 380 | 750 | ||||||

| 18 bar | m³/h(1 bar,15 °C)LAR m³/h(1 bar,15 °C)LIN |

190 140 |

380 140 |

750 280 |

||||||

| 18 bar | m³/h(1 bar,15 °C)LOX | 180 | 180 | 360 | ||||||

| 18 bar | m³/h(1 bar,15 °C)LAR | 180 | 180 | 360 | ||||||

| Capacity of one safety valve at 1.1 MAWP / cold condition | ||||||||||

| 18 bar | Kg/h LIN Kg/h LOX Kg/h LAR |

1090 1010 1240 |

||||||||

| 18 bar | Kg/h LIN Kg/h LOX Kg/h LAR |

5610 2260 2850 |

||||||||

| Insulation | Insulating powder(Perlite(,vacuum <5*102mbar(tank in operation) | |||||||||

| Main Material | Inner vessel | Low temperature resistant Stainless Steel | ||||||||

| Outer vessel | Carbon Steel | |||||||||

| Diameter | mm | 1560 | 1610 | 1980 | 2410 | 2410 | 3060 | 3060 | 3060 | 3060 |

| Height | mm | 4190 | 7150 | 6560 | 5870 | 7630 | 5400 | 6370 | 7340 | 8305 |