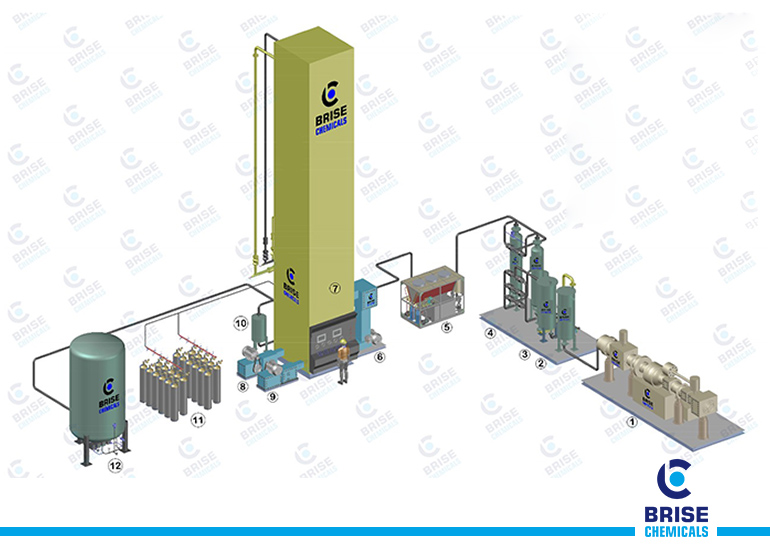

Cylinder Filling ASU Plant

Description

- 1. Compressor

- 2. After Cooler

- 3. Waste Gas Cooler

- 4. TSA Skid

- 5. Chiller

- 6. Expander

- 7. Cold Box

- 8. Liquid Oxygen Pump

- 9. Liquid Nitrogen

- 10. Defrost Heater

- 11. Filling Station/Supply Manifold

- 12. Liquid Nitrogen Storage Tank

Air Separation Unit (ASU) is used in a variety of fields to produce high-purity oxygen, Nitrogen, argon, and other rare gases through a combination of adsorption purification, cryogenic distillation, and internal compression of high-pressure products. This process plays an important role in the production of electricity, pharmaceuticals, and chemicals. Due to lower energy consumption and fewer operational risks, this process reigns supreme among others. Air Separation Unit manufacturers in India, like Brise Chemical, produce the crème de la crème of cylinder filing ASU plant in India.

It allows you to maximize your return on investment while meeting all of your process requirements. The stable operation and dependability of the cylinder filing ASU plant in India mean that once commissioned, all you have to do is let it run at peak performance. It helps in reducing energy consumption vastly on one hand while also lowering operational costs on the other, thus eliminating the risk of downtime.

Features:

A cylinder filing ASU plant in India can produce 100 to 5,000 tonnes of oxygen per day with purity levels ranging from 95% to 99.5 percent or higher.

The Following Are the Main Steps in the Air Separation Process:

- Filtration is used to remove dust and other impurities.

- Compression Which compresses air between 4 and 150 Bar g with inter-stage cooling temperature assembly to lower the temperature rise.

- Removal of Contaminants By using a constantly regenerated molecular sieve bed, it removes any remaining water vapor, hydrocarbons, and carbon dioxide that would freeze and plug the Cryogenic equipment

- Heat Exchange In which air is passed through integrated heat exchangers and cooled against product and waste cryogenic streams to produce oxygen and nitrogen-enriched liquefied air. We accomplish this through refrigeration in separate low- and high-pressure distillation columns.

- Product Compression Which compresses oxygen to a predetermined settled

pressure. - Storage involves storing the liquid oxygen produced by the Air Separation Unit in cryogenic insulated storage tanks.

The materials inside an Air Separation Unit will vary depending on the production capacity, purity, and pressure requirements for the application. For example, we use Various steel grades depending upon Temperature-pressure application. Also, it is cost-effective.

Infrastructure Requirements for a Cylinder Filing ASU Plant in India

- Cooling water during the manufacturing process, an evaporative cooling water system (either open or closed) is required to cool the compressors and process air.

- Electricity to maintain the cryogenic temperatures required for the process, an ASU requires a large amount of energy (either from electricity or other fuel sources). A 1,200-metric tonne per day ASU, for example, consumes more than 16 megawatts of power when in operation, necessitating the installation of a dedicated power supply by a local utility company.

Brise Chemical being the best air separation unit manufacturer in India, guarantees high purity air with its cylinder filing Air Separation Unit that can help you achieve improved performance and lower operating costs.

Industry-wide Application

- Oil & gas Industry

- Chemical Industry

- Healthcare Industry

- Iron & Steel Industry

Product Offering

| Technical Specification Chart | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sr.No. | MODEL No. | PRODUCT (M3/HR) |

OXYGEN | NITROGEN | CYCLE PRESSURE | COMPRESSOR | |||||

| DELIVERING PRESSURE | GOX 150-160 barg |

LIN 6-20 barg |

MP GAN 6 barg |

HP GAN 20-155 barg |

(BAR_g) | APPROX COMPRESSOR POWER(kw)* | |||||

| PURITY | 99.50% | 99-99.999% | 99-99.999% | 99-99.999% | |||||||

| PLANT CAPACITY(M3/HR) | |||||||||||

| 1 | BCON104L6 | 100 | 100 | 60 | 40 | 45 | 119 | ||||

| 2 | BCON1515L2 | 150 | 150 | 20 | 155 | 45 | 180 | ||||

| 3 | BCON2030L3 | 200 | 200 | 30 | 170 | 150 | 20 | 208 | |||

| 4 | BCON2535L4 | 250 | 250 | 40 | 180 | 180 | 20 | 260 | |||

| 5 | BCON3565L5 | 350 | 350 | 50 | 400 | 280 | 20 | 364 | |||

| 6 | BCON5095L6 | 500 | 500 | 60 | 560 | 400 | 20 | 520 | |||

| 7 | BCON60120L7 | 600 | 600 | 70 | 700 | 520 | 20 | 624 | |||

| * Delivery Pressure And Power can be customized as per customer requirement • Design Conditions 1. Design Temperature = 45 °C 2. Design Pressure = 1.014 Barg 3. Wet Bulb Temperature = 30.1 °C 4. Dry Bulb Temperature = 45 °C 5. Relative Humidity(%)=70% 6. At Sea Level |

|||||||||||