Green Ammonia Plant

Technical Specification

| Parameter | Specification |

|---|---|

| Technology | Haber-Bosch process |

| Ammonia Production Capacity | 1 TPD to 200 TPD |

| Operating pressure | 150Bar- G – 300 Bar-G |

| Final Product | Green Ammonia (NH₃), Purity: 99.99% ( custom 6 N) |

| Ammonia plant efficiency | 85 % |

| Specific Energy Consumption | Based on input details received from client |

| H2: N2 Feed Ratio | 3:1 |

Appliction

- Fertilizer production

- Energy storage

- Fuel for power generation

- Marine and heavy-duty transport fuel

- Chemical industry feedstock

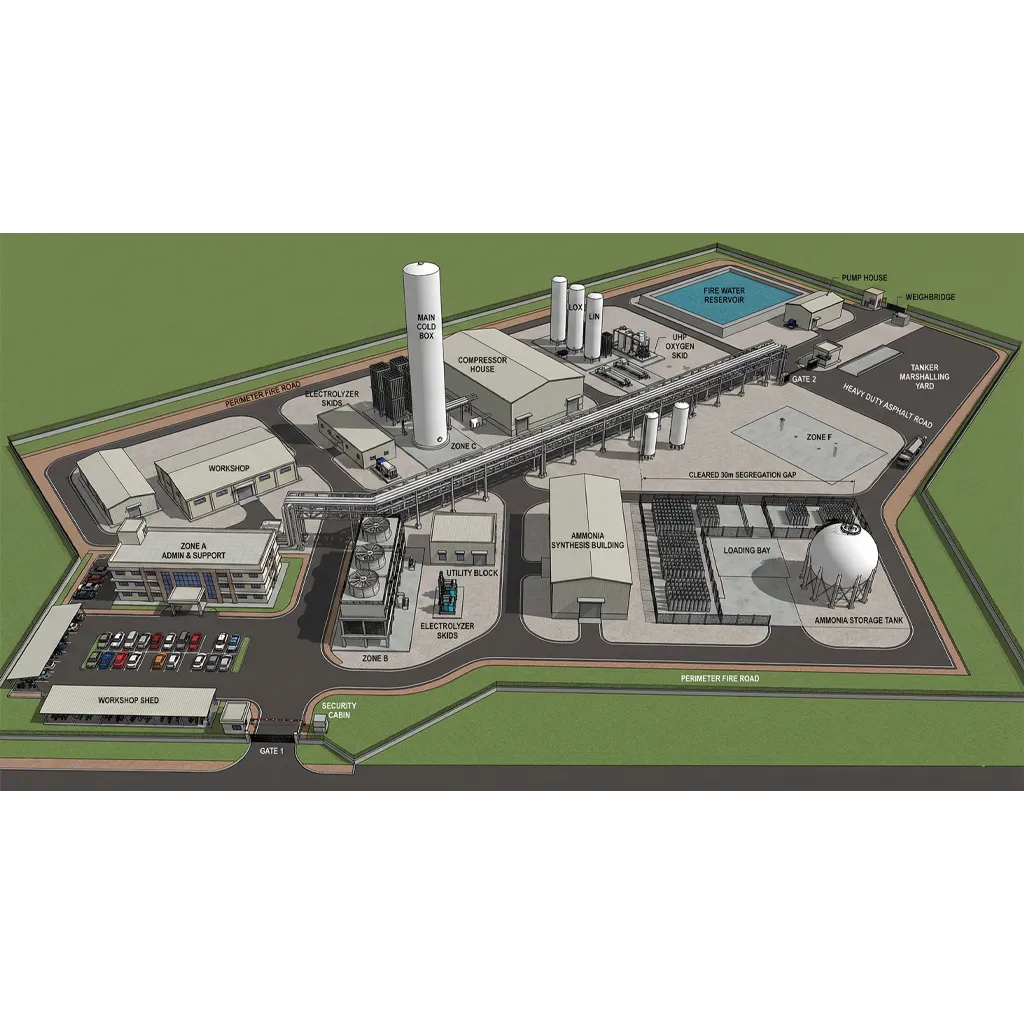

Process Description

Our integrated system efficiently produces hydrogen, nitrogen and ammonia for industrial applications. Hydrogen and nitrogen are purified and compressed before integrating in reactor. The H2 and N2 gas is then combined in a high- pressure mixer and is further sent to the Haber–Bosch reactor for ammonia production. The ammonia gas produced is then further cooled in a high purity cryogenic distillation to liquid ammonia which is then separated, collected and stored, ready for downstream applications in chemicals, fertilizers and energy industries. The system is designed for high efficiency, safety and continuous operation, ensuring consistent, high-quality output. It provides a reliable solution for industries aiming for sustainable and scalable production.